Cooking Oil extraction method

Mechanical pressing method:

Cold pressing: Castor beans are pressed at normal or lower temperatures. This method can better retain the nutrients and biologically active substances in castor oil, but the oil yield is relatively low. Generally, the oil content of the seeds is about 45% to 60%, which can be squeezed out. Castor oil obtained by cold pressing is of higher quality and can be directly used in fields with higher quality requirements such as medicine and cosmetics, but the production efficiency is low.

Hot pressing: Usually the castor seeds are heated by hot air at about 120°C to adjust them to a lower humidity, and then pressed in a hydraulic press or screw press to obtain castor oil. Hot pressing can increase the oil yield, generally reaching about 45%, but high temperature may affect some of the nutrients in castor oil.

Solvent extraction method: Using the properties of organic solvents (such as heptane, hexane, petroleum ether, etc.) that can dissolve grease, the castor seeds are extracted in a Soxhlet extractor to obtain castor oil. This method has a high oil yield and can extract most of the oil in castor seeds, but it requires the use of a large amount of organic solvents, and complex solvent recovery and refining processes are required to ensure the safety of the oil and quality.

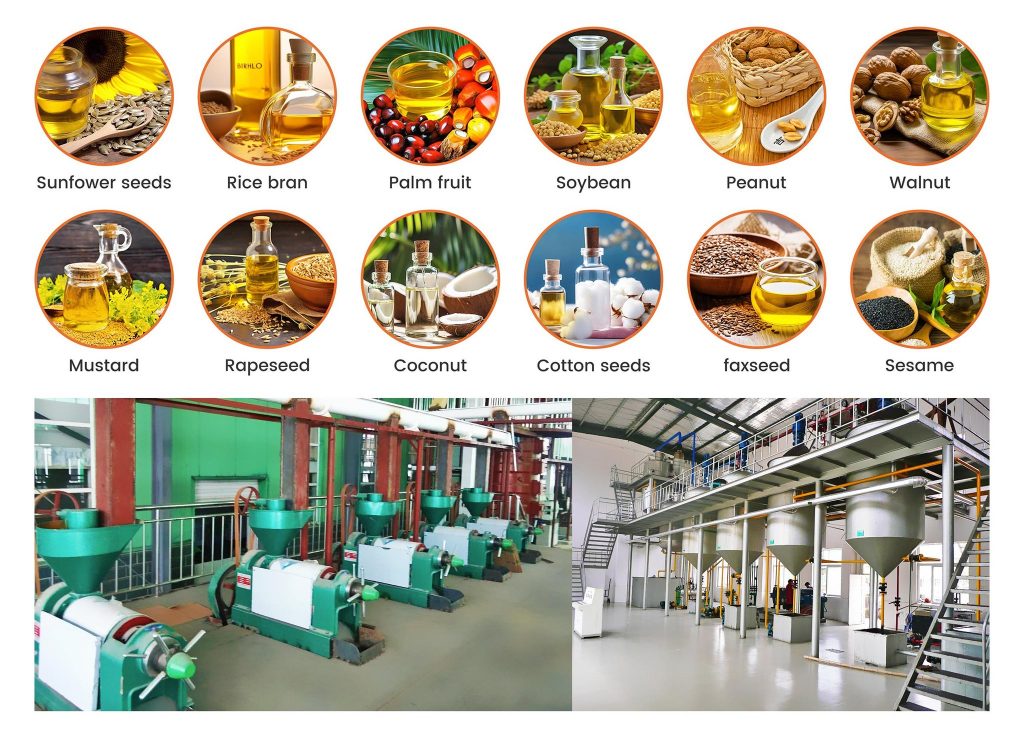

Henan Huatai supply edible oil processing machine, palm oil machine, castor oil machine, soybean oil machine, mustard oil machine, copra oil machine, any need please email to info05@cnoilmachine.com