China's largest edible oil processming machine manufacturer

China's largest edible oil processming machine manufacturer

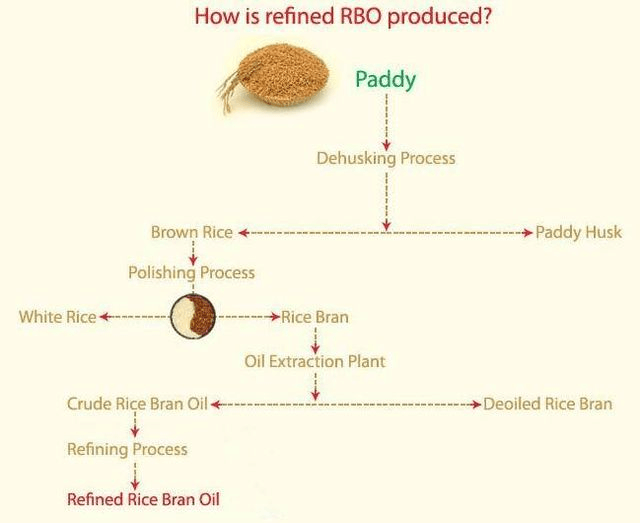

Rice bran is the by-product of rice milling, the oil contents are different due to the different varieties and difference in the number of inclusions in rice bran, which is usually 12% – 20%.Rice bran oil mill plant includes pretreatment, extraction and refining process to get edible rice oil.

Rice bran oil extraction line adopts expansion extraction technology to produce rice bran oil. Rice bran oil plant includes rice bran pretreatment and expansion workshop, rice bran oil solvent extraction workshop and rice bran oil refining workshop. The rice bran oil production line uses the rice bran expander to make the rice bran into porous expanded particles, which improves solvent permeability and extraction efficiency. Using negative pressure evaporation system and mineral oil system, it has the characteristics of energy saving and good crude oil quality. Physical deacidification and deodorization technology is adopted in rice bran refinery, which has high refining yield, light color and good quality.

Pretreatment : Clean out the sand, broken rice, straw ropes, plant straw and other debris contained in the rice bran to avoid damaging or clogging the extraction equipment and affecting the oil yield. At the same time, the rice bran must be preheated in advance to adjust the moisture and temperature of the rice bran to achieve a suitable state for oil production.

Expanding: Feed the pretreated rice bran into the puffing machine. The powdered rice bran undergoes high pressure, friction, expansion, etc. to change the shape of the rice bran and polymerize it into a porous and air-permeable columnar shape. structure. After expanding, the cell tissue of rice bran is destroyed and the internal pores are larger, which is conducive to solvent extraction.

Adopting expansion technology in the rice bran oil production line can increase extraction efficiency, reduce residual oil rate in the meal, increase the capacity of the oil extractor, reduce power consumption and improve the quality of the extracted rice bran oil.

Rice bran oil extraction usually adopts solvent extraction process. Rice bran oil solvent extraction method is a process that uses the principle of solid-liquid extraction, uses organic solvent (n-hexane), sprays and soaks the rice bran to make it fully contact with the rice bran, and extract the oil from the rice bran. The puffed and dried rice bran enters the rice bran oil solvent extraction machine to get the mixed oil, and due to the solvents with different melting points in the oil to obtain crude rice bran oil through evaporation, stripping, condensation recovery, etc. However, the crude rice bran oil contains various impurities and solvent residues during rice bran oil solvent extraction process, so the crude rice bran oil still needs to be refined.

Main process

1.Solvent extraction system

To extract oil from rice bran(use hexane to react with oil from rice bran)

2.DTDC system desolventizer toaster drier cooler system

To process wet meal, separate solvent from wet meal, then dry, cool, finally meal will be sent to meal warehouse, the oil residue in meal is less than 1%, the meal is for animal feed.

3. Miscella process system

Use separate solvent and oil. Solvent will be sent to recovery system for recycling, oil will be sent to oil refinery plant.

4. Condenser and recovery system

To recycle solvent.

Rice bran crude oil→phosphoric acid degumming→ washing and drying→ dewaxing→ decoloring→ physical deacidification and deodorization→ degreasing→ refined oil

Refining: Huatai rice bran refining process uses physical refining, including hydration degumming, washing, drying, decolorization, filtration, deacidification, deodorization, dewaxing and other processes. The rice bran refining device developed and produced by Huatai Oil Machine can reduce the refining amount of caustic soda and activated carbon, and can also reasonably reduce the peroxide value to avoid oil discoloration and acid return in the process of high temperature deodorization.

The dewaxing process of rice bran oil

There are three methods for dewaxing rice bran oil: filter press filtration,bag filter and centrifugal separation.The bag filter method is to put the cooled oil into a bag,and the bag is suspended in the air.The oil flows out from the holes of the bag, while the wax remains in the bag,thereby achieving the purpose of oil and wax separation.

Henan Huatai Cereals and Oils Machinery Co., Ltd. has obtained a number of patents in rice bran oil production line, including the production method of first grade rice bran oil refining and complete sets of first grade rice bran oil refining equipment.

Huatai Oil Machinery, was founded in 1988, which is a large-scale oil project manufacturing enterprise.