China's largest edible oil processming machine manufacturer

China's largest edible oil processming machine manufacturer

Sunflower seeds is a common oilseeds, in which there are 45-54% oil content. Sunflower oil, with golden color, clear and transparent, fragrance oil, is a kind of popular edible oil among people. How to make sunflower oil using sunflower oil production machine? There is the main process of sunflower oil production line.

Huatai complete sunflower oil production line capacity 10-5000TPD can be customized for design, manufacturing, installation and debugging.

Sunflower seeds screening

Select clean sunflower seeds with oil content of 30~50%, and remove impurities (precipitate, stone, iron filings, etc.) contained in the seeds by cleaning sieve and magnetic separator.

Shelling & crushing

Sunflower seeds should be pressed after shucking, which can improve production capacity and oil quality. After the sunflower seeds are screened, they are shelled in a sheller. Then through the grinder to crush into a certain granularity of sunflower seed particles.

Rolling and steaming

Roller embryo is the grinding of sunflower oil seeds into a certain thickness of the embryo, its role is to destroy the cell tissue, so that the oil is easily extracted.

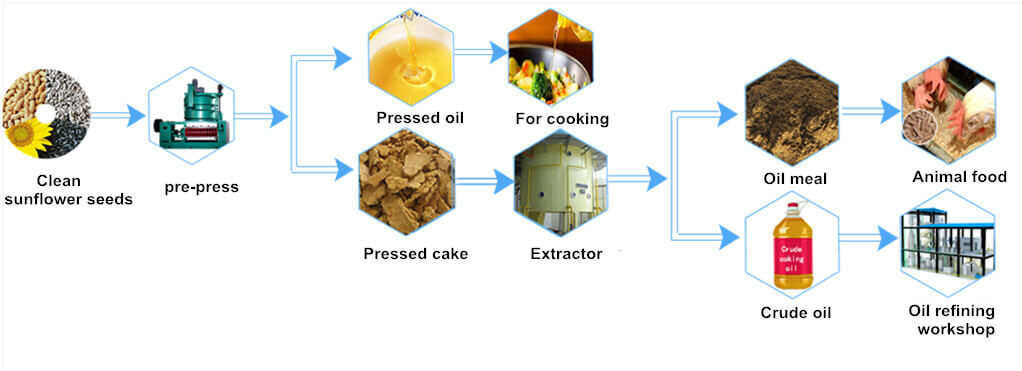

Pre-press and extraction

After pre-extrusion, the structure of extruded cake is loose but not crushed, which is conducive to solvent penetration for extraction process.

The quality and economic benefit of the oil extracted by the pre-pressing and extraction process are better than that of the oil extracted by single pressing or single extraction.

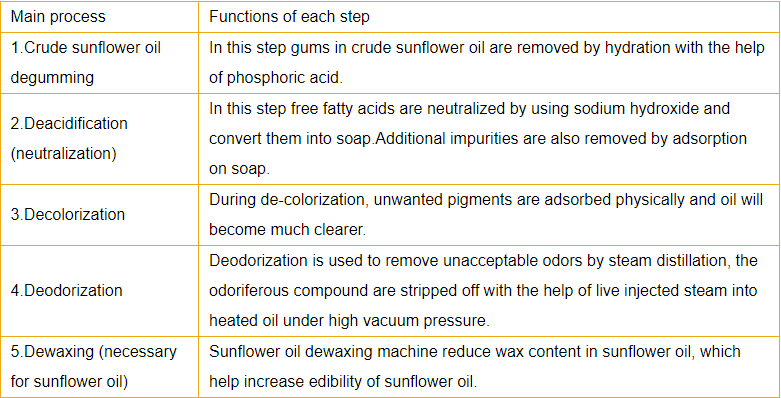

The steps of sunflower oil refining mainly include degumming, decolorization, deodorization and dewaxing. The refined oil has light color, high nutritional value and good taste.

The sunflower oil refining workshop needs to be equipped with a complete set of sunflower seed oil refining equipment, the main equipment of which includes: dephosphorization and degumming Dehydration pot, decolorization pot, soap stock pot, deodorization tower, clay tank, crude oil tank, filter oil pump, vibration filter, air compressor, heat exchanger, thermal oil furnace, etc.

Dewaxing in the refining process: The sunflower oil after deodorization process also contains a small amount of wax, which is pumped into the pre-cooled crystallization tank and cooled at a certain cooling rate within 8 hours. After the oil is cooled and crystallized to a certain temperature, the crystal retention time is maintained for 12 hours in the crystallization tank. After that, the oil and wax are separated by a filter press, and the resulting oil is a finished sunflower oil, which meets the standard of high-grade edible oil.

Huatai Oil Machinery, was founded in 1988, which is a large-scale oil project manufacturing enterprise.