Description

Coconut oil, also known as copra oil, is an edible oil extracted from the kernel or meat of mature coconuts harvested from the coconut palm, Coconut oil is called the healthiest edible oil in the world. Filipinos call coconut oil “the drugstore in a bottle.”

Coconut oil (copra oil) has wide applications in food and chemical industries, therefore, it is produced in many areas. In the year 2012, world coconut oil production was 49300000, which is almost 15times of the year 2000 (3310000 tons); Indonesia is the world’s largest supplier of coconut oil, followed by Philippines, India, Brazil, and Sri Lanka.

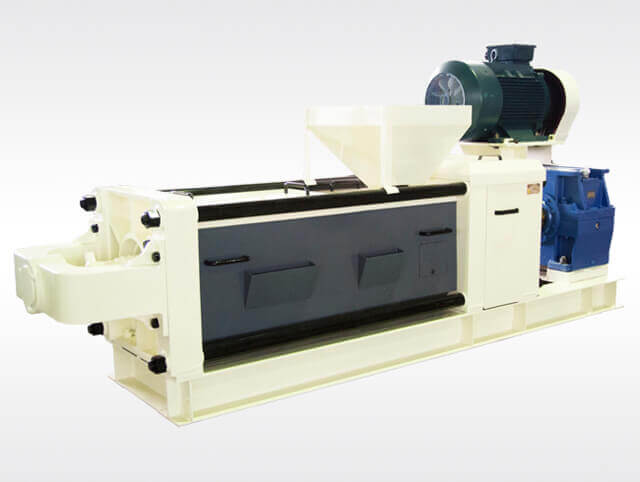

Huatai Copra oil mill plant mainly includes three processes: the pretreatment of oil, extracting and refining.

Coconut oil pretreatment processMain steps

Copra→cleaning→crushing→steaming and frying→ pre-pressing→ twice pressing→crude oil

Coconut oil refining plant Main steps

Coconut oil mill plant mainly includes crushing section, steaming and stir frying section, extracting section, degumming section, deacidification section, decoloration section and deodorization section.

Coconut oil production process

Main processes include: Seed Cleaning & Weighing, Copra conveying, Conditioning, Flaking, Cooking, Pressing, Oil Residue Separation.

The raw material copra are blocks, so they are not suitable to be delivered by elevator; the small scraper conveyor has too small inlet, therefore the feeding will be unsmooth; while if the scraper is too big, it will cost too much. That’s why we choose belt conveyor for the coconut oil making line. Its slant angle should not exceed 30°, otherwise it is easy to fall out material. Before the crushing device, we install an iron removal device, which can on one hand prevent the equipments from being damaged by irons, one the other hand guarantee coconut oil cake quality.

Copra is big block dried coconut meat, whose size can be 180mm x 100mm x 6mm. Therefore, we should first solve the problem of copra breaking. We choose hammer crusher, and increase screen size, reduce the number of hammers, and arrange hammers crossover uniformly. Copra has high oil content, so we use chain elevator for the transport of the material after crushing. Also because of the high degree of powder, the import and feed nozzle are easily piled up or even blocked; therefore, the inlet and outlet pipes are designed with observation window, for convenient observation and unchoking.

Copra is a high oil content material. if the rolling distance is too small, it is easy to get oil, but after crushing and conveying, the oil has been infiltrated in the surface of material, so they are easy to clot and adhere to roller, resulting in roll feeding difficulties or even blocking; and at the same time, the copra is too dry, hard, tough and has small density, if the rolling distance is too small, the material will be piled between the two rollers. Therefore, the flaking of copra is different from other oil materials, its rolling distance is larger, about 3 to 4.5mm, to avoid the high degree of powder, adhere to roller and unsmooth material discharge.

Due to the continuous stirring of steam cooking machine, the oil tend to flow out from the copra, and drip down along the principal axes, resulting in waste and workshop environment pollution; at the same time the material is easily clotted and cause difficulty to transmission. Solution: reduce the degree of material powder, decrease stirring time, and frequently clean up the feeding nozzles of steam cooking machine and elevator, to prevent the build-up of material.

Due to the distinct material properties of copra from common oil materials, if we process it in conventional way, there may result in no feed, no cake out or there is any oil squeezed out at the pressing cage, so the pressing bar clearance needs to be adjusted. When pressing copra, the gap between the pressing bars must be small.

Coconut oil clarifying & filtering

Copra has high fiber content, so the crude coconut oil contains too many dregs. In order to reduce the filter burden, in the coconut oil production process we add a oil clarifying process, so that the dregs directly go back to the oil press for re-pressing.

Coconut oil introduction

The main component of coconut oil is lauric acid (about 50%). It is also the main component of the fat in breast milk. It is the healthiest oil and has no harm to human body. Lauric acid is a kind of medium-chain fatty acid, which is easy to decompose and absorb, not hoarding, and it is quite stable, not easy to deteriorate. Coconut oil has strong antibacterial activity against bacteria, viruses and even gastrointestinal parasites in the body.

Coconut oil is suitable for children, the elderly and those who are weak and resistant to infection.

Coconut oil has many magical effects. Coconut oil is saturated fat, lipid stability, not easy to oxidize to produce free radical attacks, it can be used for beauty and anti-aging, this kind of oil has a strong antioxidant capacity, which can help prevent the production of free radicals, both oral and external use can moisturize the skin.