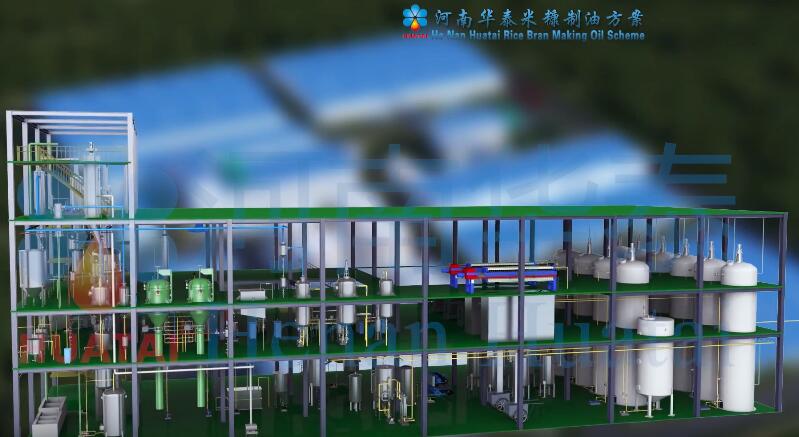

Full continuous cooking oil refining equipment 3D workshop

With the progress of the times, all the continuous refining equipment has been applied in more and more industries. What is the process flow of the continuous oil refining equipment? What are the main equipments in the whole continuous oil refining workshop? What are the main economic and technical indicators for a full continuous cooking oil refinery? What are the characteristics of full continuous cooking oil refining equipment? Today Xiaobian is here for you briefly:

Fully continuous refining equipment main features: high degree of production automation, good quality of finished oyster oil, and suitable for daily processing of 50 tons of soybean oil, rapeseed oil, cottonseed oil and other bulk oils.

Fully continuous refining equipment can complete hydration, alkali refining, water washing, decolorization and deodorization process operations, and adopts advanced technologies such as electronic measurement, high-speed centrifuge de-soap, vacuum (continuous) drying, etc., mainly used for pre-extraction-leaching and The rapeseed oil, rapeseed oil, peanut oil, and flax oil, such as rapeseed oil produced by a leaching process, and the refining of animal fat such as lard, butter, and sheep oil, are also suitable for rice bran oil and sunflower oil.

The main equipment of the full continuous refining workshop: centrifuge, decolorization tower, deodorization tower, blade filter, four-stage steam jet pump, and water jet pump.

Full continuous refining equipment Technology features: The refining process is mainly decolorization and deodorization process stages. After the alkali refining oil is dried in a vacuum drier, it is heated by a plate heat exchanger into a continuous decolorization tower, decolorized by bleaching, and the decolorized oil is pumped into the blade filter. Then send it to the safety filter.

The decolorizing oil is pumped into the deaerator to remove the air, enter the heat exchanger to exchange heat with the deodorized oil, and then enter the deodorization tower after entering the heating oil heater to heat. The deodorized oil is withdrawn from the bottom and pumped into the heat exchanger to exchange heat with the deodorized oil. After cooling, the product oil is obtained.

Full-scale continuous refining equipment main process introduction:

1. Water Eluting Adhesive and Deacidification Section:

Neutralization: Gross oil is exported from the oil tank with an oil supply pump. After metering, it enters the oil-oil heat exchanger to recover part of the heat. It is then heated by the heater to the required temperature of the process. The measured amount of phosphoric acid or citric acid from the phosphoric acid tank is The mixture (M401) is mixed and then transferred to the conditioning tank (R401) to convert the non-hydratable phospholipids in the oil to hydrated phospholipids; then it is neutralized with alkali, and the amount of alkali and lye are added to the mixture. quality. The neutralized oil is heated by a heater to a separation temperature (90° C.) into a centrifugal separator to remove phospholipids, FFA, and other impurities from the crude oil. The oil goes into the washing process.

Washing: The neutralization oil from the neutralization separator still contains about 500 ppm of soap. In order to remove these residual soaps, add about 5-8% hot water to the oil. Usually the hot water temperature is higher than the oil temperature. 3- 5°C. In order to make the water washing effect more stable, phosphoric acid or citric acid is added during the water washing, and the oil and the flooding mixer are re-mixed and heated by the heater to 90-95° C. to enter the water washing separator to separate the residual soap and most of the water, containing soap, The oil’s water enters the oil-water separation tank, traps the oil, and is further captured by the outdoor oil catching tank. The waste water is discharged to the sewage treatment station.

Vacuum drying stage: The water washing oil from the water washing separator still contains a small amount of water that is not stable to the oil. In order to remove these moisture, the oil at 90° C. is sent to a vacuum desiccator for vacuum dehydration. The dehydrated oil goes to the decolorization process. Dry oil extraction pump selection shielded pump.

2. Continuous decolorization process:

The main function of the decolorization process is to remove the pigment in the oil, residual traces of soap particles and metal ions. Under the condition of negative pressure, the combination of mechanical agitation and steam agitation is used, and the decolorization effect is more obvious.

The degumming oil is first heated into a heater and heated to a suitable temperature (110°C) into a clay mixing tank. White clay is transported from the low earth box through the wind to the clay temporary storage tank. The addition of white clay is automatically measured, and it is interlocked with the oil inlet control. The oil is mixed with clay and overflowed to a continuous decolorizer. The decolorizer uses unpowered steam agitation. The bleached oil enters two alternately used leaf filter filters. The filtered oil passes through the safety filter and enters the decolorized oil storage tank. The decolorized oil storage tank is designed to have a nozzle inside the vacuum tank to prevent the decolorized oil from contacting the air and affecting its peroxide value and color return.

3. Continuous refining deodorization process:

The qualified decolorizing oil enters the spiral plate heat exchanger to recover most of the heat and enters the deodoriser after entering the high pressure steam heater and heating to the process temperature (240-260°C). The deodorizing tower is a combined type, and the upper structured packing is mainly used to remove odor components such as free fatty acids, and the lower layer is a plate tower, which mainly plays the role of thermal decolorization and removes the peroxide value in the oil to zero. The oil from the deodorization tower absorbs most of the heat after the heat exchanger and then further exchanges heat with the crude oil. Then it is cooled to 80-85° C. by a cooler, and the required antioxidants and flavors are added and then cooled to below 50° C. . Volatile substances such as fatty acids deodorized are trapped with a packing trap, and the trapping liquid is a low-temperature (60-75°C) free fatty acid. When the level of the fatty acid temporary storage tank is high, it is sent to the fatty acid storage tank for storage.

The main economic and technical indicators of the full continuous refining workshop:

1. Steam consumption ≤120kg/T oil (refining) can reach 95kg at the lowest:

Alkali refining ≤25kg/T oil

Decolorization ≤25kg/T oil

Deodorization ≤70kg/T oil

Electricity consumption ≤15KWH/T oil (refining) are:

Alkali refining ≤ 9KWH/T oil

Decolorization ≤3KWH/T oil

Deodorization ≤3KWH/T oil

2. Water consumption: (soft water) 150Kg/T oil (refining)

3. Compressed air 30M3/hour

5. Coal consumption 23 Kg/T oil

6. Phosphoric acid dosage 0-2 Kg/T oil

7. Alkali consumption Acid price × 1 Kg/T oil

8. White clay consumption 5-20Kg/T oil

9. Waste clay soil content <28%

10. The amount of circulating cooling water is about 100M3/h (refining)

11. Refining losses

(1) Degumming loss = glue content × 1.2

(2) Deacidification loss = acid price × 1.2 (chemical refining) Deacidification loss = acid price × 0.6 (physical refining)

(3) Decolorization loss = amount of white clay × 0.25%

(4) Deodorization loss ≤ 0. 5%

More questions about full continuous refining equipment, please feel free to contact us!