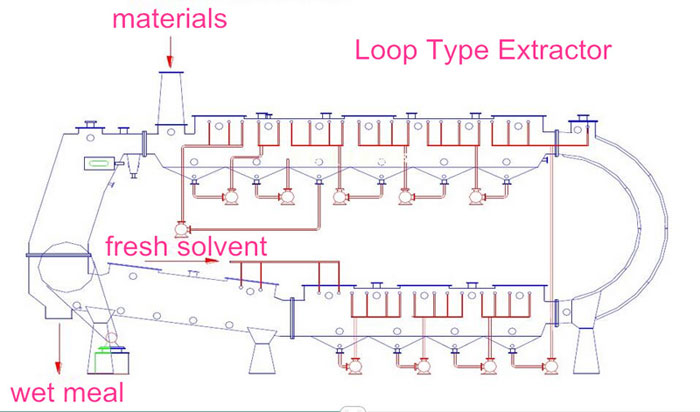

Loop type extractor

Adapt large oil plant for extracting, its biggest characteristic is the oilseeds from the bending section to turn into the substratum, makes extracting oil more uniform thoroughly, shallow layer, wet meal with less solvent content, residual oil amount to less than 1%.

Specification of oil extraction machine: 30-5000TPD

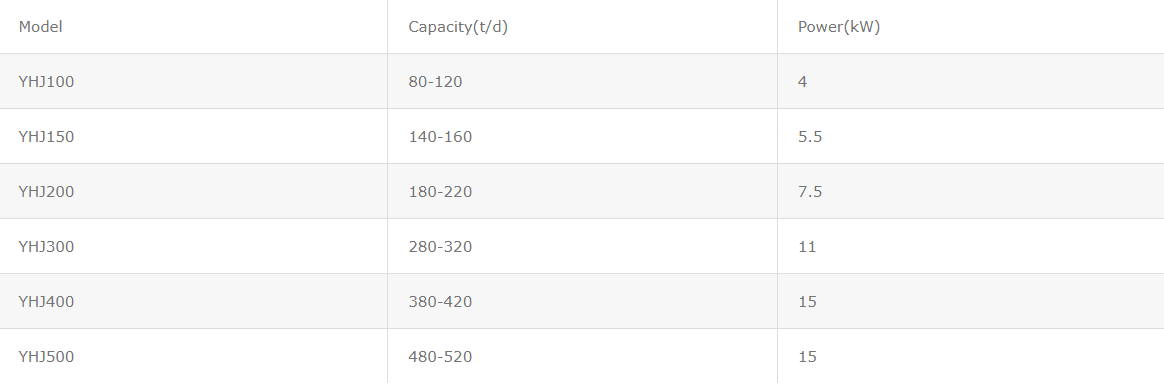

Technical Data

Application Range: Pressed cake, flakes, expanded oilseeds and all low oil-content oilseeds, such as: soybean, rice bran, corn, cottonseed, etc.

Product Details

Oil extraction technology can be classified into batch extraction and continuous extraction in terms of operation mode, immersion extraction, percolation extraction, and combined extraction in terms of contact mode, direct extraction, pre-pressing extraction, and expansion in terms of production technology. We provide rotocel extractors, loop type extractors, drag chain extractors, and tank extractors to meet your edible oil plant needs.

Loop type extractor is a continuous combined type extractor suitable for large scale oil extraction plant, dragging by the drag chain conveyor, the materials ratate for one cycle to complete the extraction process. Loop type extractor is suitable for the oil extraction of peanut, rapeseed, cottonseed, sunflower seed, corn germ, camellia seed, flaxseed, soybean, rice bran, etc.

Advantages

1. Adopt chain drive, low ratating speed, smooth running without noise, low maintenance cost.

2.The materials are turned over twice during the extraction process, the extraction is more uniform and sufficient.

3.Shallow material layer promotes fast permeating and draining of solvent and miscella, short extraction time, low solvent content in the wet meal and low residue oil rate.

4.The feed system automatically adjusts the ratating speed of the main engine by incoming amount, so that the materials can maintain a certain level in the buffer bin, promoting the formation of negative micro-pressure inside the extractor and reducing the leakage of solvent vapor.

5.Adopt advanced miscella circulation design, conductive to reduce the input of fresh solvent, reduce residue oil in meals, increase miscella concentration, and save energy by reducing the amount of evaporation.

6.Materials feeding and meal discharging is uniform and continuous, ensuring the stable pressure inside the extractor.

7.The machine can be made by sections, convenient for transportation and on-site assembly.