Palm Oil Fractionation

Palm Oil Fractionation Process

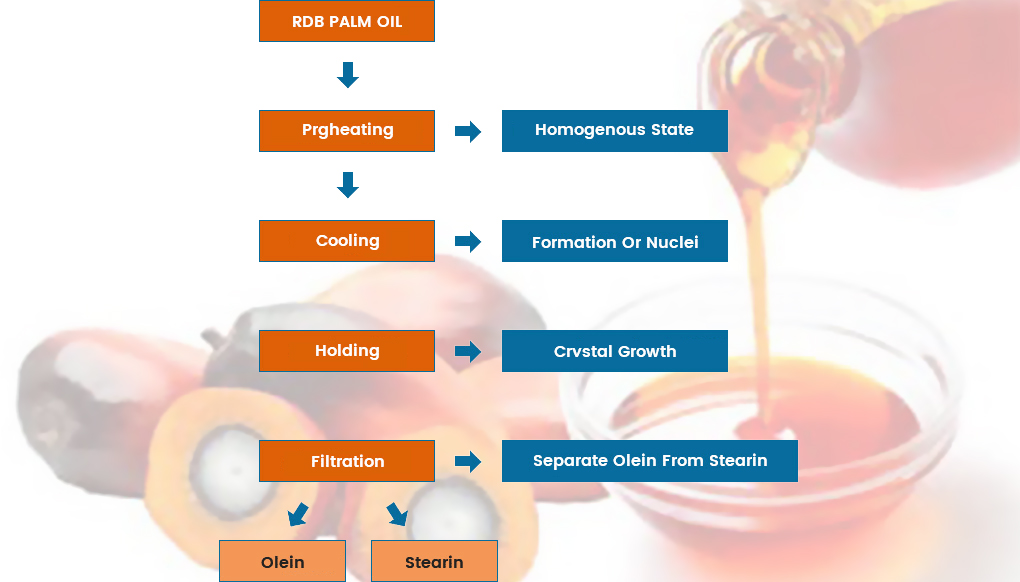

Heat Palm Oil: Palm oil is semi-solid at room temperature and dissolves into a liquid state by heating with steam. Before crystallization, palm oil is usually heated to around 70°C to break up existing crystals.

Cooling And Crystallization: The key to the palm oil dry fractionation process is cooling crystallization. If crystallization is successful, separation will be easy. Therefore, under the conditions of stirring and circulating water cooling, the cooling process should be controlled by setting the temperature difference between the oil and cooling water and the cooling time, so that it can form crystal nuclei and grow slowly. Cooling stops when the desired temperature is reached.

Filter: It is important to control the cooling and crystallization conditions, and the choice of filtration equipment also has a great influence on the yield of liquid oil. At present, the filtration systems used in industry are: drum filter, continuous belt vacuum filter and membrane filter.

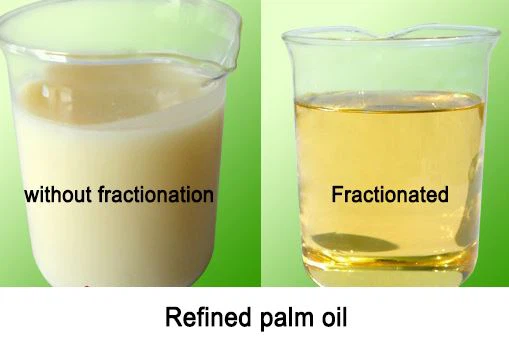

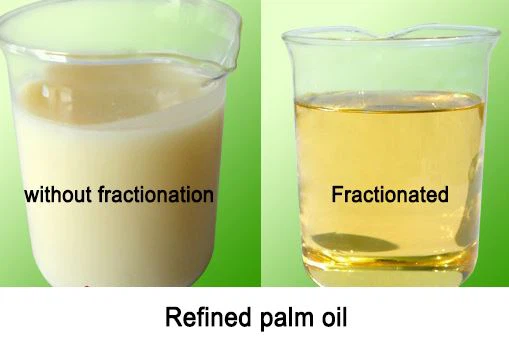

Dry fractionation is used to separate RBD palm oil into olein and stearin. The typical process consists of a crystallisation section and a filtration section. During crystallisation, RBD palm oil is heated and then cooled under a controlled cooling program. The fractionation system uses a vertical cylindrical vessel full of water which is temperature regulated and mechanically agitated at a low speed. When the palm oil enters the vessel, crystal formation and growth occurs as the oil is agitated and cooled by the chilled water. The cooling rate is regulated by controlling the water temperature. The oil becomes a slurry of crystals and remaining liquid oil. The slurry is then fed into a plate and frame type filter press to separate the RBD palm stearin from the RBD palm olein. The solid crystals of the palm stearin are retained on the filter plates.

Dry fractionation has the advantages of simple process, high degree of automatic control, low steam consumption, good product quality, no need for centrifugal separator, no other solvents, and no waste water.