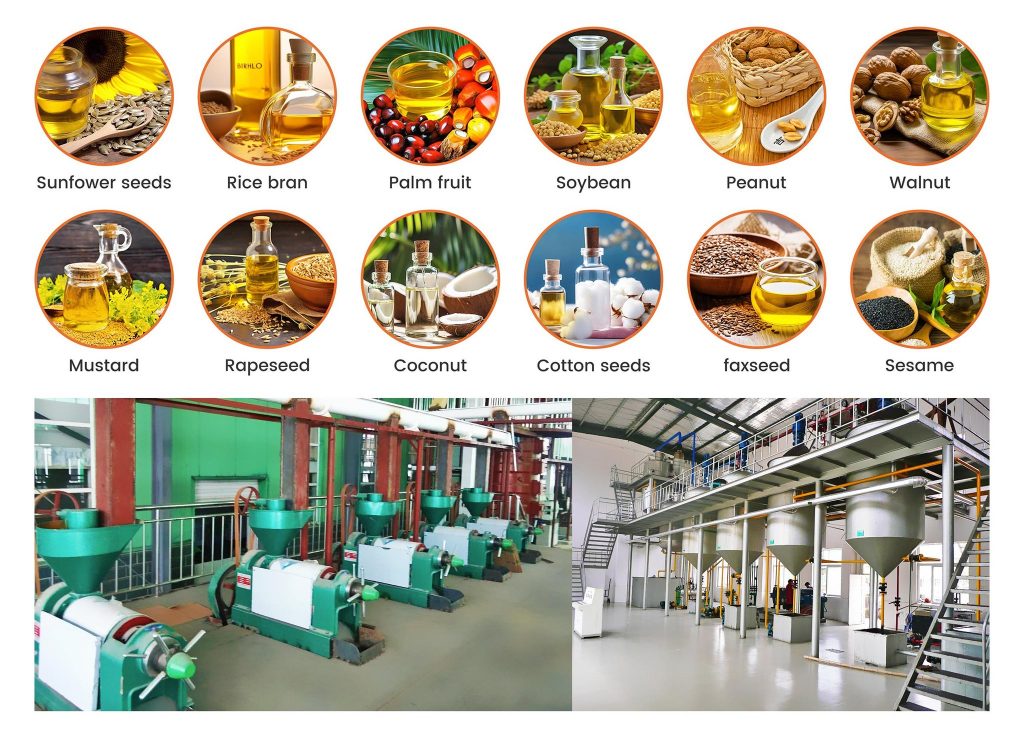

Sunflower oil Production process

Preprocessing:

Cleaning and screening: Use vibrating screens, magnetic separators and other equipment to remove impurities, stones, iron filings, etc. in sunflower seeds.

Shelling and crushing: Use a shelling machine to separate the sunflower seed shells, and then use a crusher to break the kernels into suitable particle size.

Pressing: Use a screw press or hydraulic press to press the crushed nuts to obtain crude oil and oil cake. During the pressing process, parameters such as temperature and pressure must be controlled to increase the oil yield.

Refining:

Degumming: Add an appropriate amount of water or phosphoric acid to the crude oil to coagulate and precipitate colloidal impurities such as phospholipids, and remove them by centrifugation.

Deacidification: Using alkali refining method, use sodium hydroxide solution to neutralize the free fatty acids in the crude oil, generate soap stock and then separate and remove it.

Decolorization: Use activated clay, activated carbon and other adsorbents to remove pigments and impurities in the oil to make the oil lighter.

Deodorization: Under high temperature and high vacuum conditions, the odorous substances in the oil are removed through steam distillation to improve the quality of the oil.

Filling: The refined sunflower oil is measured and filled, and an automated filling production line is used to improve production efficiency and packaging quality.

Equipment selection

Raw material processing equipment: vibrating screens, magnetic separators, shellers, crushers, etc., are selected from well-known brands to ensure stable equipment performance and strong processing capabilities.

Pressing equipment: Choose the appropriate model of screw press or hydraulic press according to the production scale, which has the characteristics of high oil yield and low energy consumption.

Refining equipment: degumming tanks, deacidification tanks, decolorizing towers, deodorizing towers, etc., using advanced technology and materials to ensure the refining effect and oil quality.

Filling equipment: automated filling machines, labeling machines, capping machines, etc., to achieve efficient and precise packaging operations.

Other equipment: conveying equipment, storage tanks, measuring equipment, testing equipment, etc., to meet the needs of material transportation, storage, measurement and quality testing in the production process.

Environmental protection and safety design

Environmentally friendly design:

Wastewater treatment: Establish a complete sewage treatment system to treat production wastewater and discharge it after reaching standards. At the same time, water resources are recycled to reduce water consumption.

Waste gas treatment: Treat the waste gas generated by boiler rooms, refining workshops, etc., and use desulfurization, denitrification, dust removal and other equipment to reduce pollutant emissions.

Waste residue treatment: Comprehensive utilization of oil cake and other waste residues produced during the pressing process, such as as feed raw materials or raw materials for organic fertilizer production, to reduce waste residue emissions.

Complete sunflower oil processing, sunflower oil production line, crude oil refining plant design, any need please email to info01@cnoilmachine.com