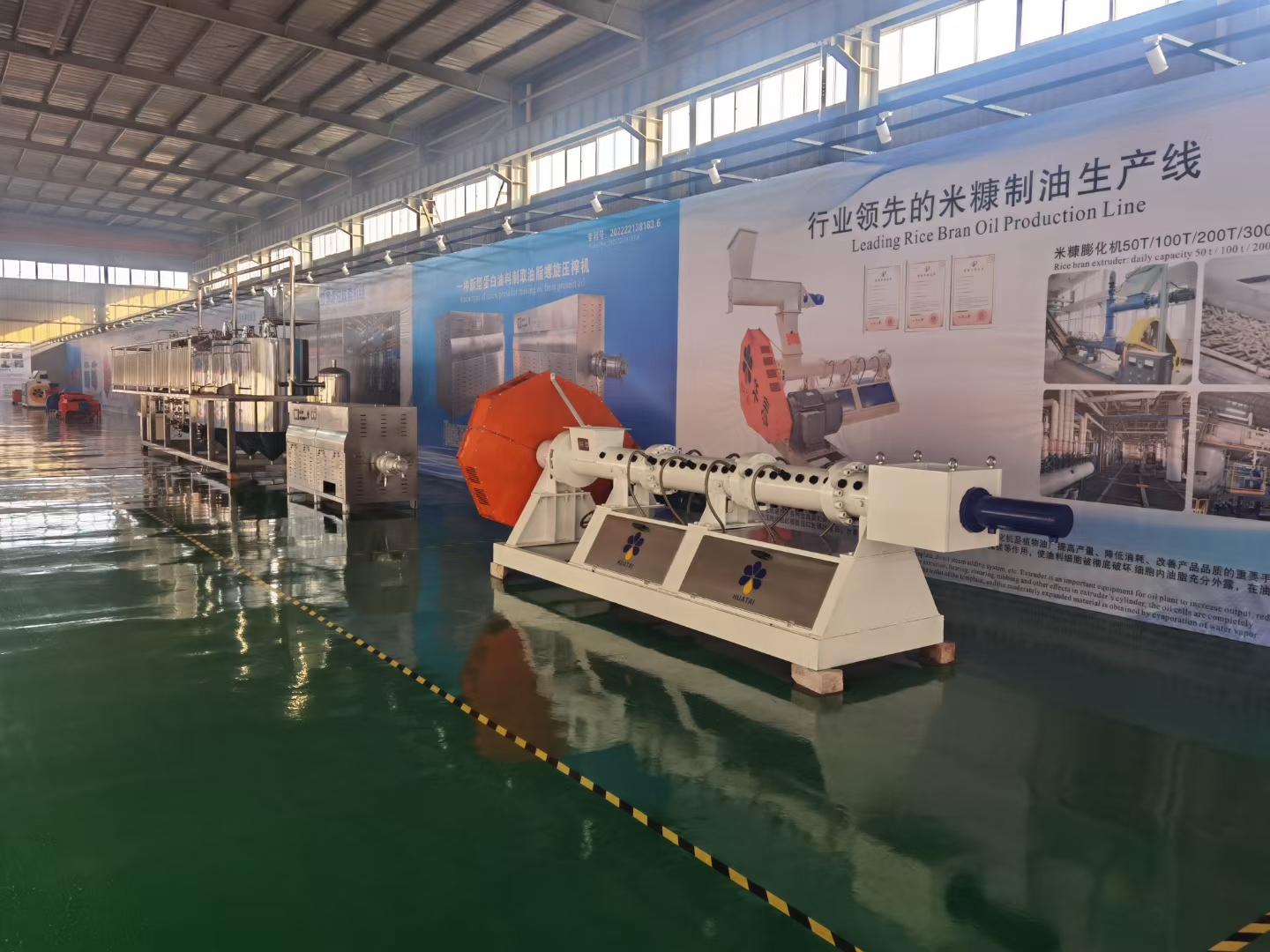

Oilseeds extruder

Oilseeds extruder is mainly used for oilseeds pretreatment and various kinds of pre-pressed cake before extracting oil , such as rapeseed, corn germ which contains high oilcontent . pretreatment section of Rice bran oil extraction machinery especially need this equipment ,it can improve the oil yield efficiency and improve product quality, reduce the loss of the equipment.

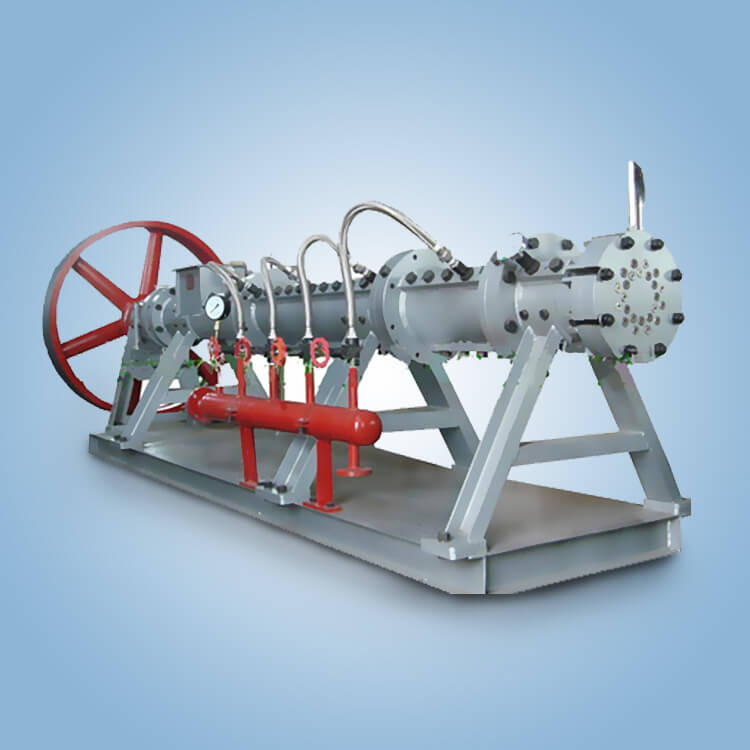

The oil is extruded and puffed, and the oil is pretreated before leaching the French oil. In the dry extrusion extrusion machine, the oil is kneaded, sheared, extruded, and puffed. The cells of the oil are completely destroyed, leaving the oil molecules in a free state. The starch is gelatinized and the protein structure is formed with certain mechanical strength, easy penetration, and ease of use. Drip-dry, powder-free, microporous granules.

It is generally used for the pretreatment of rice bran, soybeans, etc., which can improve the processing capacity of the leaching equipment and reduce the residual extraction rate in the meal.

The puffing pretreatment process is one of the oil Solvent extraction processes. During production, the oil can be processed into a cooked embryo with a certain structure and shape through the puffing process. The puffing can destroy the oil cells and make the oil form a porous and strong clinker embryo. Thus, the permeability and leaching rate are visually changed during leaching. The expansion process can also speed up the bulk density, thereby speeding up the processing capacity of the leaching equipment, inhibiting or passivating enzyme activity, and benefiting the stability of oil during storage and processing.

The puffing and solvent extraction process of rice bran oil

Rice bran raw materials – Cleaning – Conditioning – Extrusion and puffing – Solvent extraction

Cleaning: The main purpose is to remove sand, stones, straw, broken rice and other impurities in the rice bran to avoid damaging and clogging the puffing machine, which will affect the puffing effect.

Conditioning: After the rice bran enters the inkjet printing machine, the rice bran is preheated in advance and the moisture content of the rice bran is adjusted. The moisture in the rice bran, the machine temperature and the ambient temperature all have a certain impact on the work of the puffer. Among them, the moisture in the rice bran determines the elasticity and plasticity of the puffed material.

Puffing: Puffing refers to injecting high-pressure steam and high-temperature water into the puffing machine to increase the temperature and humidity inside the puffing machine, so that the powdery rice bran polymerizes into porous materials through instantaneous effects such as high temperature, high pressure, shearing, friction, and expansion. , columnar structure with good air permeability.

After puffed rice bran, the cell tissue is completely destroyed, the puffed material particles are stronger, the powderiness is small, the bulk density is larger, the interior has more porosity, the outer surface has more free oil, and the strength and mechanical cavity are increased. During leaching, the permeability of the solvent to the material layer is greatly improved, and the leaching rate is increased, which can increase the output of the leaching device and shorten the leaching time; the small dissolved-to-material ratio can reduce solvent consumption and gas consumption when the mixed oil evaporates; leaching The resulting wet meal has low dissolved content, which can reduce the compliance and steam consumption of the wet meal desolvation equipment. At the same time, lipase, lipoxygenase, phospholipase and other enzymes in rice bran are more completely passivated, which reduces the acid value of the leached crude oil. During storage, the acid value rises to full, and the content of non-hydrated phospholipids is reduced, which reduces the Solvent extraction crude oil. Oil quality improves.

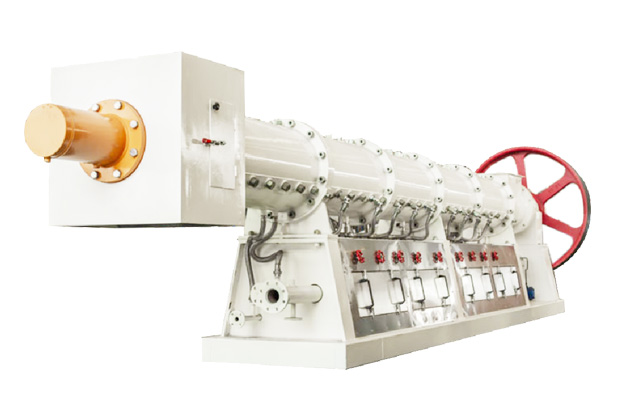

Soybean Extrusion and puffing

Before Solvent extraction, soybeans must be cleaned, crushed, softened, rolled, steamed and fried to obtain soybean embryos. At this time, the embryos can be directly used to extract oil, or they can be extruded and puffed into puffed particles before Solvent extraction Oil making.

Soybean puffing and solvent extraction process

Before Solvent extraction, soybeans must be cleaned, crushed, softened, rolled, steamed and fried to obtain soybean embryos. At this time, the embryos can be directly used to extract oil, or they can be extruded and puffed into puffed particles before Solvent extraction. Oil making.

The expansion Solvent extraction process can improve the leaching efficiency, reduce steam consumption, increase the refining rate, and the quality of the finished product is also better. After the puffed oil cells are completely destroyed, the oil is on the surface of the puffed material, which reduces the leaching time, increases the production capacity of the leaching equipment, and is beneficial to the leaching of oil.

During the puffing process, soybeans are subjected to high-temperature friction and humid heating with high-temperature water vapor, which effectively destroys the phospholipids and oxidative enzymes in the soybeans and accelerates the transformation of non-hydrated phospholipids into hydrated phospholipids. The crude oil produced in this way contains non-water The content of phospholipids is greatly reduced, which can increase the refining rate of oil during refining. Moreover, soybeans are subjected to high temperature and short-term heat treatment during the puffing process, and these enzymes are inactivated to varying degrees. The passivation of urea destroys the activity of toxic components and anti-nutritional substances in soybean meal and improves the quality of soybean meal.

Soybean Extrusion and Puffing Technology

The puffing technology can often be seen in the production of rice bran oil and soybean Solvent extraction. The soybean puffing and Solvent extraction production line has a series of advantages such as high efficiency, large output, high oil yield, and good oil quality.

There are significant differences between puffed soybeans and soybean meal in terms of processing methods, nutritional content, uses and prices.

Processing method: Puffed soybeans are feed products made by puffing whole soybeans by wet or dry methods. This process denatures the protein of soybeans, gelatinizes starch, exposes fat, and is rich in oil. High temperature and high pressure kill pathogens. It retains the nutrients of soybeans, has extremely high nutritional value, and is a substitute for fish meal. Soybean meal is a by-product of soybean oil extraction. The main processing methods include heat treatment and mechanical processing.

Purpose: Extruded soybeans are mainly used as feed raw materials. Its high heat energy, high protein and high digestibility make it a high-quality protein raw material in livestock and poultry feeds. In addition to being used as feed, soybean meal is also widely used in food additives, agricultural fertilizers and other fields. More than 80% of domestic soybean meal is used to raise poultry and pigs.

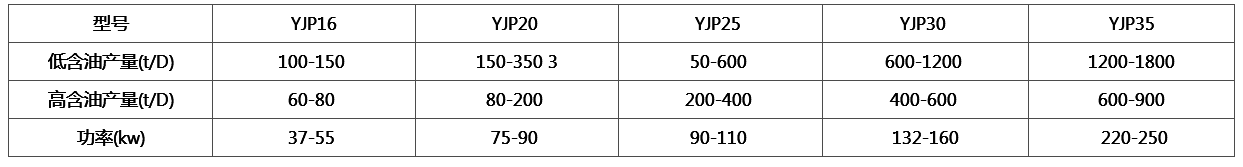

Technical Data

We have more than 200 running oil processing plant around the world and have extensive experience in oil mill construction. If you are interested in our Oilseeds Extruder, please leave us a message.