Sub-critical Fluid Extraction Equipment

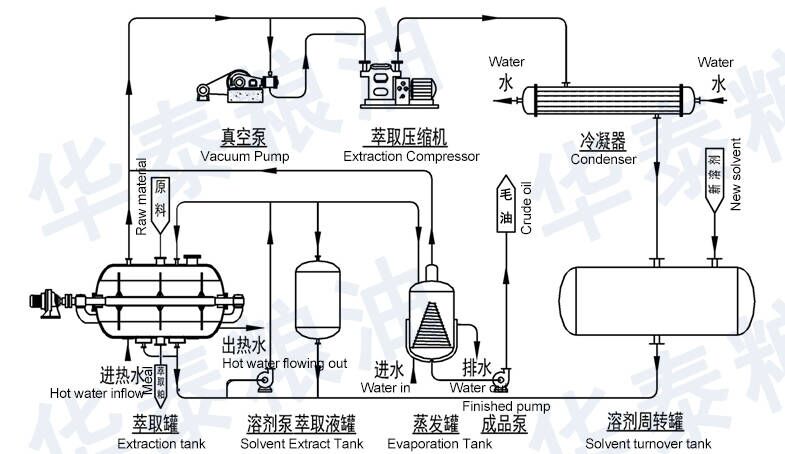

Sub-critical fluid extraction technology is a new extraction and separation technology by using subcritical fluid as extracting agent, based on the principle of similar miscibility of organic compounds in the pressure container of airtight,low pressure and anaerobic, then get the final product.Sub-critical fluid extraction technology is a kind of new oil extraction technology, not only provides the high quality raw materials for vegetable protein factory, but also provides a new way for Precious oil with good quality.

Sub-critical fluid extraction technology has many advantage: avirulent, harmless, environmental protection, no pollution, retaining extract active products not damage, no oxidation products, large capacity, energy saving, low running cost, easy separation with product.

The most widely used subcritical low-temperature extraction of plant pigments is the extraction of lutein from marigolds and marigolds(Marigold Lutein Extraction Line), which has basically become a standard configuration in this field. Using subcritical low-temperature extraction technology, the lutein pigment will not be destroyed, and the lutein yield is higher than the traditional No. 6 solvent leaching method.

The second step is to extract capsicum red pigment from the pepper skin(Capsicum Annuum Extraction Line). The pepper skin contains both red pigment and capsaicin. A mixed solvent is used for extraction.The meal after subcritical low-temperature extraction of red pigments and capsaicin can be used as condiment filler and spiciness regulator.

Subcritical extraction line customized design services

1. Special subcritical extraction design for different raw materials

2. Optimized subcritical extraction design for different outputs

3. Optional designs with different levels of automation

4. Targeted design for different national cooking oil standards

5. Installation and training services for ancillary subcritical extraction line

We have more than 200 running oil processing plant around the world and have extensive experience in oil mill construction. If you are interested in our Sub-critical Fluid Extraction Equipment, please leave us a message.