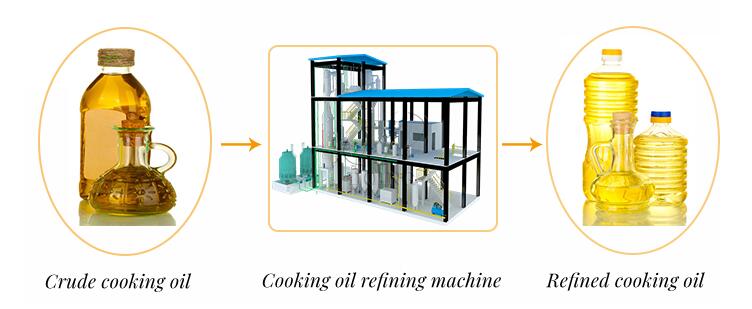

Continuous cooking oil refinery

Crude cooking oil include free fatty acids, glue, peroxide, water, and cake residue in pancakes and so on. Through cooking oil refining process, the purified cooking oil would meet the standard of country’s cooking oil and could be sold in the market.

Continuous cooking oil refinery is the newest technology to refine edible oil. Comparing with batch oil refinery and semi-continuous oil refinery, it has following advantages.

1.The oil consumption in the whole process is less.

2.The whole process can be controlled by computer, so the big capacity can be processed per day.

3.The consumption of auxiliary matters is reduced, so the running cost is lower.

4.The auxiliary matter is added according to the crude oil by the computer. The oil quality is more stable.

5.The degree of automation is improved. The floor space is less than batch oil refinery and semi-continuous oil refinery.

Cooking Oil Refinery Steps

Degumming: The oil after degumming is heated to 110¡æ. Then the oil is sent to white clay mixing tank. The white clay is transported to clay storage tank from the white clay box. The white clay is added by the quantity of oil.

Disc centrifugal: The disc centrifugal is the central part in the degumming. The whole line includes both chemical and physical way.

Centrifugal mixer: The centrifugal mixer can mix the materials completely. It also can finish the process in a short time. The combination of short mix and long mix ensure the effect of refinery.

Vacuum dryer: The stainless steel vacuum dryer is used to move the water in the oil.

Decolorization tower: In the continuous oil refinery, the decolorization tower is used to light the color of the oil. The meters of this tower is saving energy and reduce the vacuum leak.

Deacidification and deodorization system: Deodorization section is very important for producing high quality cooking oil. The technology of deodorization influence the oil quality. This deodorization tower can move both the free fatty acid and keep the good smell of the cooking oil. At the same time, this tower can save the direct steam. The consumption of steam is only 30-50% of the normal tower.

Cooking Oil Refinery Techinical Data

| Consumption Item | Capacity |

| Recycling water | 140-150T/h |

| Water consumption | 0.25-0.3T for processing one ton oil |

| Electricity | 82.5KWh for processing one ton oil |

| Steam (pressure 6kgf/cm2) | 490-520kg for processing one ton oil |

| Coal | 15-17kg for processing one ton oil |

| Phosphoric acid (80%) | 1-2kg for processing one ton oil |

| White clay | 3-5Kg for processing one ton oil |

| Citric acid | 0.5-1kg for processing one ton oil |

The continuous cooking oil refinery is suitable for large scale oil plant, used widely for 30-600tpd, It can process various kinds of oil seeds, such as soybean, peanut, corn, rapeseed, cottonseed, etc. The whole way is continuous and the oil consumption is less. It also can used to get different standard cooking oil. Henan Huatai Group supply cooking oil intermittent refining, edible oil semi-continuous refining, large capacity edible oil continuous refining for customer’s detail needs.