The palm oil is obtained by pressing the fresh palm fruit.Palm fruit into a bundle of growth, each bundle about 20-30kg weight contains 1500 to 2000 fruit.Farmers pick the palm nuts by cycle and must be transported to the factory on that day.The quality of palm oil depends on the integrity of the palm fruit bunches, palm fruit once the damage will be rapidly deteriorated, thus affecting the quality of palm oil.

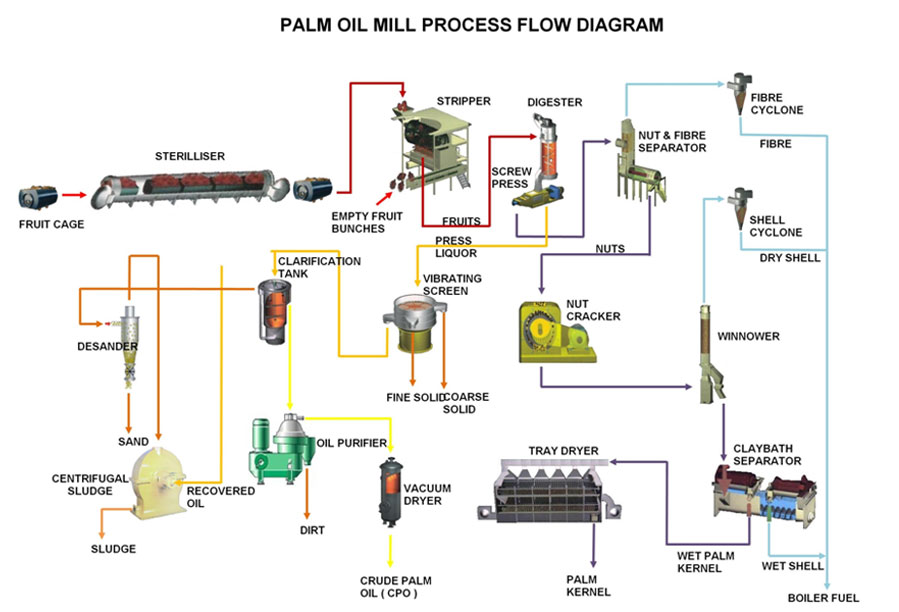

The main products of the palm oil press are the palm oil and palm kernel, the processing capacity of about 60 to 100 tons per hour of palm fruit bunch.For crude palm oil, the general to go through sterilization, threshing, cooking, pressing, washing, purification, drying and other processes.

For palm kernel, after the separation of the press, but also through the fruit / fiber separation, nuclear quenching and tempering, broken nuclei, nucleolus separation, palm kernel drying process.

Henan huatai palm oil processing main processes: weighing, unloading fruit, FFB Sterilizer, removing fruits, mashed, pressing, shell and kernel separation, water treatment, palm oil refinery and fractionation,filling.

Henan huatai palm oil processing machine main features:

1, Our company adopts hydraulic segmented discharge in palm fruit unloading, cleaning, storage platform;

2, Palm fruit oil press machine adopts double helix hydraulic continuous discharging, greatly improving the production efficiency;

3, The use of diesel generator and steam turbine generator is more environmental protection and energy saving, electricity power for production and life;

4, Our water treatment system, through sedimentation, filtration, dosing process, ensure the quality of the water, also ensure the quality of palm oil;

5, Adopting the remote substation technology, more energy efficient, improve the production efficiency.

Specifications: 5TPH,10T/H,30T/H,45T/H,60T/H,80T/H,100T/H(TPH); Any need please email to info01@cnoilmachine.com