The production process of coconut oil mainly includes cold pressing method and refining method.

Cold pressing is a physical extraction method that usually uses fresh coconut meat and physically presses it at low temperatures to obtain virgin coconut oil. This method does not add any chemicals or undergo high-temperature processing, so it can retain the natural ingredients and nutritional value of coconut oil to the greatest extent. Cold-pressed coconut oil is in a clear and transparent liquid state with a natural coconut flavor and is commonly used in food, cosmetics and health care products. Because cold-pressed coconut oil is unrefined, it may be darker in color and contain some impurities and trace ingredients.

Refining involves chemically extracting coconut oil, usually using dried coconut meat. This method includes multiple steps, such as degumming, decolorization, deodorization, etc., to remove impurities and odors from coconut oil and obtain purer coconut oil. Refined coconut oil is usually in a light yellow or colorless transparent liquid state without coconut flavor and is suitable for use in cooking and industrial production. It should be noted that chemical solvents and high-temperature treatments may be used during the refining process, which may cause certain loss and damage to the nutrients in coconut oil.

In general, cold pressing and refining are two different coconut oil production processes, each with its own advantages and disadvantages. Cold-pressed coconut oil retains its natural ingredients and nutritional value, and has a natural coconut flavor, but is darker in color and contains impurities. Refined coconut oil is purer and suitable for use in cooking and industrial production, but its nutritional content may be affected to a certain extent. loss and damage. The choice of coconut oil depends on the consumer’s needs and uses.

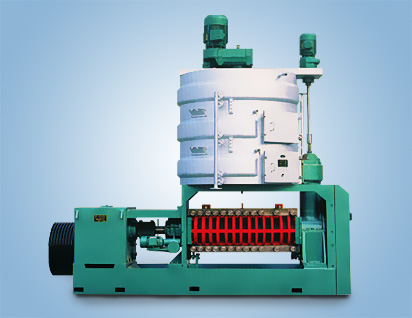

Henan Huatai supply copra oil press machine, coconut oil machine, copra oil refining, any need please email to info05@cnoilmachine.com