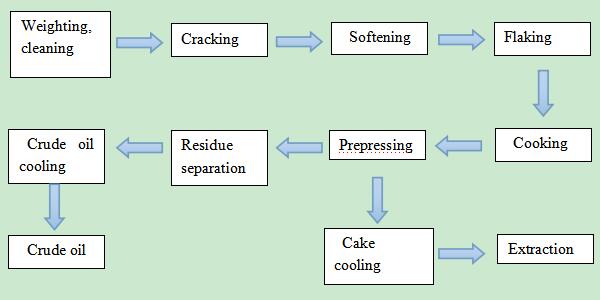

Rapeseed, flaxseed pretreatment and prepressing plant

Rapeseed, flaxseed pretreatment and prepressing process

Weighting section

Adopts bucket continuous measurement system, ensure the accuracy of raw materials production and processing cost is accurate.

Condition section

Vertical softening pot is made of several layers of pan monomer, the structure of each layer is basically the same, have edge interlayer and bottom interlayer, steaming into the interlayer to heating, softening materials.Softening pan center has a vertical axis through the layers, each layer pot monomer has two mix paddle fin fixed on the vertical shaft, to stir up material layer. Each layer pot body floor open a blanking hole, blanking hole in each layer are with automatic door, by controlling the falling rate to control the material layer height of each layer. At the same time, each layer pot body wall has exhaust pipe , they are common connected to the exhaust manifold, to discharge the water vapor in the softening process.

Flaking section

After crushing the shell of rapeseed, flaxseed, the seeds fall into flaking machine allocation scraper, assigned to the hydraulic rolling machine. In the process of flaking, under the effect of extrusion and knead burst, the oilseeds cell wall ruptured and release the oil in the cell, pressed into thin slices greatly reduces the way of the oil flow out , so the extraction is easy to get oil. But the embryo isn’t the thinner the better, if too thin, the rapeseed, flax seed will flow out oil, sticky glue roller, can make the embryo powder degree increased, reduce the solvent penetration speed, and flaking machine power consumption also increased, so we need control a reasonable thickness. In the actual operation, it can be flexible adjustment according to the operation condition of the equipments.

Cooking section

Cooking function mainly is: on the basis of flaking has already broken part cell, through the swell and heating, the oil cell rupture, thereby further damage fuel cells, prompted protein fully condensed degeneration of oil, colloid damage, so the highly scattered small oil can release from the continuous Colloid, gathered into larger oil.

Cooking mainly is vertical cooking pan, is make of several layers of pan monomer, the structure of each layer is basically the same, have edge interlayer and bottom interlayer, steaming into the interlayer to heating, cooking materials.Cooking pan center has a vertical axis through the layers, each layer pot monomer has two mix paddle fin fixed on the vertical shaft, to stir up material layer. Each layer pot body floor open a blanking hole, blanking hole in each layer are with automatic door, by controlling the falling rate to control the material layer height of each layer. At the same time, each layer pot body wall has exhaust pipe , they are common connected to the exhaust manifold, to discharge the water vapor in the cooking process.

Prepressing section

Prepressing adopts the screw press machine, screw press machine has characters of continuous processing, dynamic press time short, high oil yield and low the labor intensity.

The main part of the screw press is pressing chamber, pressing chamber is in pressing cage with pressing cage and screw axis of rotation. Its working process is the use of screw axis helical lead to narrow or the root circle diameter increases gradually, make the pressing chamber volume shrinking and pressing effect, the extract oil extrusion flow from a crack in the press cage, at the same time pressing the residue into crumbs bread slices, from press shaft end continuously flow out.

Oil residual separation section

Crude oil from the oil press, through the oil/sludge separation scraper, settling tank, and the blade vibration filter, the impurities content less than 0.5%. Especially the supporting blade vibration filter has high degree automation, compact structure, continuous operation, stable running, strong adaptability, large production capacity, easy maintenance, etc.

Technology characteristics

Better dust removal system, to ensure plant clean, reduce dust emissions at the same time.

More recycling measures, reduce man-made wrong operation, especially not forming cake cycle, greatly reduce the manual labor intensity when driving.

Vertical softening conditioning pot, cooking pot, covering a small area, save construction investment.

Scraping machine has anti-blocking and stall protection switch, bucket elevator has anti-blocking , stall and off tracking protection switch.

Automatic control degree is high, when subsequent transmission equipment malfunction, the conveying devicein front will automatically stop.

Gas from dust removal equipment is comply with national environmental requirements.

Part blower adopts frequency conversion adjustment, can be adjusted according to the raw material moisture content, reduce power consumption.