Safflower seed oil extraction

Introduction

Safflower seeds come from a precious herb, safflower, native to Egypt. Safflower seed oil is rich in nutrients, containing 6% saturated fatty acids, 21% oleic acid, and 73% linoleic acid. Because its main component is linoleic acid, which is the oil with the highest linoleic acid among food oils, its nutritional value is particularly high.

Benefits of safflower seed oil

Safflower seed oil is rich in vitamin E and the trace element selenium. It also contains some natural active ingredients. After people eat it, it can clean up free radicals in the body and improve the body’s antioxidant capacity. It can delay human aging. It can also prolong life.

Safflower seed oil extraction

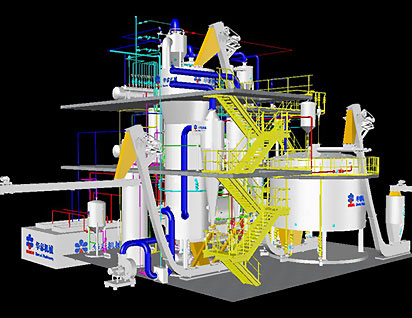

Safflower seed oil can be extracted by pressing, solvent extraction technology and subcritical low-temperature extraction method. In industrial production, safflower seed oil is mostly extracted by pressing method and solvent extraction method, which can fully extract the oil in the oil. Its technology as follows:

1. The pressing process uses an oil press to apply physical external force to the safflower seeds to squeeze out the oil, retaining the original flavor and nutrition of the safflower seeds. The production line equipment configuration can be adjusted according to the needs of the oil factory, saving investment and meeting the crude oil quality requirements. It is more suitable for high-end or small and medium-sized oil plants.

2. The solvent extraction method uses a volatile solvent to fully contact the safflower seeds to extract the oil. However, the safflower seed oil produced by the leaching method must use refining equipment to remove impurities before it can be eaten. During the impurity removal process, the safflower seed oil is The nutrition and flavor of the seed oil have a certain impact; however, the leaching process has large output, high efficiency, good cake quality after leaching, and low residual oil, so it is suitable for large oil plants with a daily output of more than 20 tons.

3. Subcritical extraction: Send the green sheet into the extraction kettle for subcritical extraction. The extraction temperature is 25~35℃, the extraction pressure is 0.3~0.5 MPa, the extraction solvent is butane, the number of extractions is 4 times, and the residual oil of the meal is <1.5%.

Safflower seed oil refining

Since safflower seed oil contains a large amount of unsaturated fatty acids, it is easy to cause oxidative rancidity of the oil and affect the oxidative stability of the oil. Therefore, the oxidative stability of the extracted safflower seed oil is poor during storage. In order to improve the quality and oxidation stability of oil, oil plants can refining crude oil. Refining has a great impact on the oxidation stability of oil. Refining can better separate free fatty acids, phospholipids, pigments, metal ions, odor substances, waxes and other substances in vegetable oil, and is an important step in the oil processing process. However, with the deepening of research, people have found that refining separates oils that are harmful to the human body and also affects the quality of the oil. Excessive refining will affect the maintenance of various active ingredients in vegetable oils, such as polyphenols and vitamin E. , sterols, phospholipids and other substances, reducing the edible value of safflower seed oil. It is understood that different refining processes have an impact on the fatty acid composition, lipid concomitant content, and in vitro oxidation capacity of safflower seed oil. After comparison, it was found that the deacidification process has a relatively greater impact.

Oil refining and deacidification refers to the separation of fatty acids that exist in free form in vegetable oils from crude oil. The presence of free fatty acids will cause the vegetable oil to become rancid and deteriorate, thereby affecting the flavor and stability of the oil. Reducing the acid value of the oil is conducive to improving the quality of safflower. Seed oil storage stability. Oil plants can ensure the quality of refined oil by choosing refining equipment manufactured with mature process technology. During the deacidification process of safflower seed oil. If the refining equipment can operate at lower operating temperatures and shorter processing times, lipid concomitants will be retained to a greater extent and the generation of large amounts of wastewater will be avoided, thereby achieving the expected production goals of the oil plant.

Choose Henan Huatai Safflower oil refining

There are many manufacturers that design and manufacture edible oil refining equipment on the market, and their capabilities vary. Choosing a reliable machinery and equipment factory is crucial for oil mills. We recommend customers to purchase equipment from Henan Huatai Oil Machinery. The manufacturer focuses on It has been producing various oil processing equipment for many years and has a mature technical team and production force that can tailor appropriate production plans for customers based on their actual conditions. If you have safflower seed production or investment needs, you must choose the type of process that meets your needs based on the area, budget, output, and oil quality of the oil plant, and choose the powerful Henan Huatai Cereals and Oil Machinery Co.,Ltd.