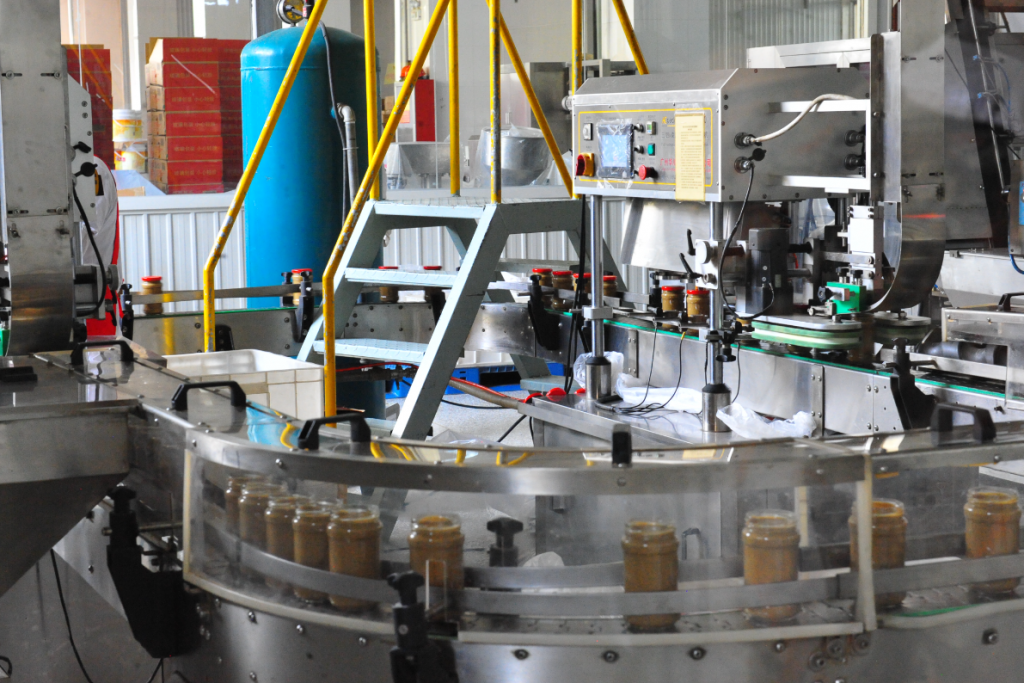

Sesame oil production line

Sesame oil content is between 40% and 58%. Sesame oil is extracted from sesame seeds and has a special fragrance, so it is called sesame oil. Its protein content is also quite high, generally 23% to 26%. The state attaches special importance to the quality and safety of sesame oil. The new national standard for sesame oil passed the assessment on November 22, 2016. The new standard recommends that manufacturers implement the principle of “moderate processing” to avoid the carcinogen benzopyrene produced in over-roasted sesame seeds.

First-level sesame oil is often produced by the “hot frying-pressing-fine filtration method”. The oil has a distinct sesame oil aroma and has the same uses as finely ground sesame oil. Due to the high oil content of sesame seeds, sesame oil is generally produced by pre-pressing with a hydraulic press and then using the leaching method in industrial production. Since sesame crude oil contains about 1% natural antioxidants such as sesamol, sesamollin, and sesamin, sesame oil has a long shelf life.

Sesame oil processing steps

Sesame → Screening → Seed frying → Smoke → Blowing → Pressing → Crude oil → Precipitation and filtration → Sesame oil

↓

Sesame cake→Second pressing

Cleaning: The purpose of cleaning is to remove impurities and immature seeds;

Frying seeds: When frying sesame seeds, it is important to control the heat, time and temperature. At the beginning, due to the high water content of sesame seeds, it is advisable to stir-fry the ingredients over high heat; when the frying degree reaches 70%, reduce the firepower and check the tenderness of the sesame seeds at any time. Generally, it is appropriate to make the temperature reach about 200°C. The cooked sesame seeds can be twisted by hand until they turn red or yellowish brown. When stir-frying, stir frequently so that moisture and smoke can be easily dispersed, preventing scorching and uneven cooking.

Smoke: When the sesame seeds are taken out of the pot, although water is poured to cool them down, the temperature is still around 140°C to 150°C. If not cooled, there is still a possibility of burning, so the heat should be dissipated immediately after taking out the pot. Hence the name “Yang Yan”. The smoke raising operation can be carried out with a smoke raising machine, and small oil plants often use manual smoke raising operations.

Blow clean: During the frying process, the sesame skins easily fall off, and there is also some fried oil powder (commonly known as sesame bran) mixed in. These substances contain less oil and mixed with sesame seeds will also affect the quality of the oil, so they must be removed. . The blowing operation generally adopts the method of blowing or screening.

The roasted sesame seeds are evenly and continuously sent to the hydraulic press for pressing, and the crude oil is squeezed out under the action of pressure. The squeezed crude oil is filtered with an oil filter to remove solid impurities to obtain clear crude oil.

Crude sesame oil refining

Filtration/refining

Refrigeration unit

↓

Crude oil → Clear oil tank → Plate filter → Cooling pot → Storage tank left to settle → Plate and frame filter → Bag filter → First-grade sesame oil

Process Description

The filtered oil is filtered at low temperature and cooled to 15~20℃ to minimize the loss of aroma volatilization. The new process of filtration, standing and filtration is adopted to fully filter out the phospholipids that are not easily hydrophilic and reduce the phospholipid content in the oil to a minimum in order to improve the stability during the storage period.

(1) First filtering. The pressed crude oil is initially removed from the clarified oil tank and pumped into the filter for filtration. The obtained primary filtered oil is pumped to the cooling pot. After cooling to a certain temperature, it is pumped into an oil tank with a cooling coil and refrigerated. .

(2) Second filtering. The oil that has been filtered once is allowed to stand to further combine the water-containing phospholipids that are easier to combine. After secondary filtration with strong water absorption, the partially polymerized phospholipids are separated to achieve the filtration and polishing effect. It makes the oil extremely transparent, improves the sensory indicators, and further improves the stability during storage. After the filtered oil is allowed to stand, it is filtered twice by a plate and frame filter to obtain the finished sesame oil.