Waste tire pyrolysis equipment Device composition

1) Heating system// main reactor

Q245R boiler steel.

The thickness of reactor is 16mm (also can adjusted accoring to your requirements).

The main engine uses horizontal-type of 360° structure -0.4r/min.

Sevral kinds of reacor designed for your choice.

2) Feeding system// auto-feeder:

Saving at least 1/3 working time.

Can feed the material during the process, which is much safer and save energy.

Double dyaulic design can increase the force area, which made the machine operatiing more

stable and have a long service life.

3) Condensing system:

The better cooling system, the more oil you can get!

4 grade condenser(1 top pipe + 2 main conensers + cooling wind tower)

inside of each condensers has 74 pieces gas pipes.

Cooling area reach to 40 square.

4) Exhaust disposal system

(1) Dedsulfurization dedusting: remove the sulphur( when use coal as fuel) and dust

(2) Water film cyclone: for the second removal and the smoke from the washer film

cyclone is white, but pollution-free.

3) Spraying de-dusting: circulating water without pollution; high pressure spray, dust absorpion; adding in alkaline and sulfur dioxide at high temperature.

5) Carbon black discharging system

Discharge the carbon black diretly and automatically;

Saving time and labor, which is much safer for workers.

6) Safety system:

Include Temperature table, Pressure gauge, Safety valve, Alarm and Water seal.

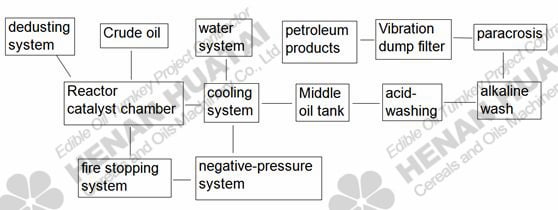

Process flow:

Oil distillation machine is consist of four main parts, which are distillate tank, energy recycling system( pre-heating tank), cooling tank and wine storage tank. Direct heating and indirectheating methods are available to choose from for the distillate tank. The energy recycling device on the top is the equipment is the main part of energy saver.

We have more than 200 running oil processing plant around the world and have extensive experience in oil mill construction. If you are interested in our Waste tire pyrolysis equipment, please leave us a message.