Corn starch Technological Process

Corn starch processing machine

Corn starch processing machine is the corn processing equipment, which includes soaking, cleaning and feeding equipment, crushing, multi-stage screening machine, dehydrator, dryer and a complete set of mechanical equipment. It is easy to operate.

The main production process includes: Corn cleaning – soaking – corn grating – germ separation – corn grinding – starch screening – protein separation and starch washing – centrifugation and drying.

Huatai can provide you with medium and large corn starch production equipment, and provide a series of complete solutions for domestic and foreign customers from market research to product selection, factory design, equipment matching, installation and commissioning production and packaging design. At the same time, we sell all kinds of related machine equipment: cyclone screen, air dryer, separator, etc.

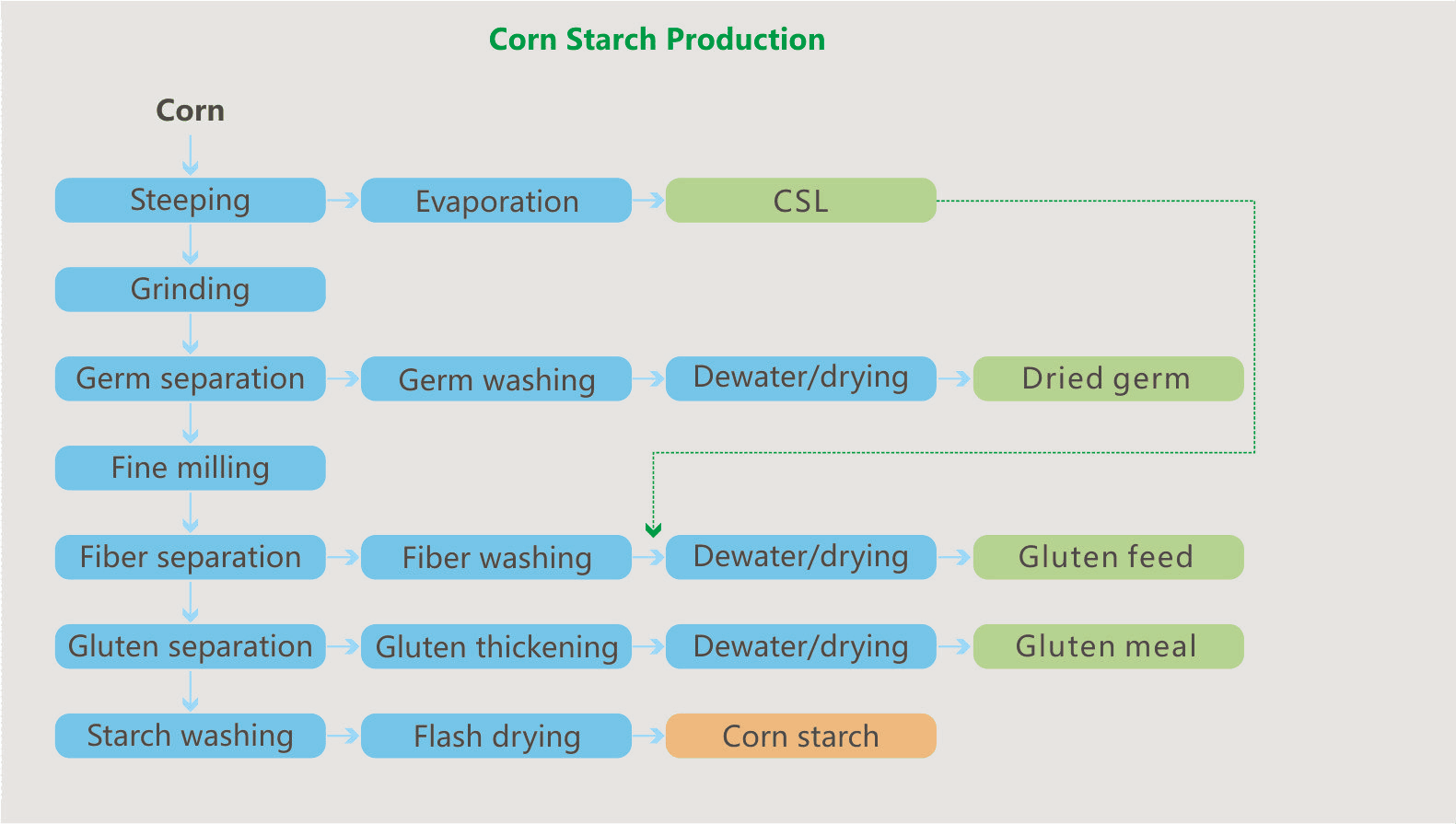

The production of maize starch

The production of maize starch will include the following operations, such as raw maize cleaning, preparation of sulfureous acid as steeping liquid, maize steeping, germ separating and drying, fiber separating and drying, gluten separating & drying and starch washing, starch drying.

Maize cleaning

The raw maize will be transported by trucks to the plant where it is metered through the truck platform weigher and used as raw material for production of maize starch. First the impurities, such as stones, iron foreign material and others, will be removed from it by the maize cleaning screen and the magnetic separator. Then it is conveyed and fed into the maize storage silos through the elevator and the apron conveyor.

Preparation of sulfureous acid

Sulfureous acid is used as the steeping liquid in the maize steeping. Sulfur is quantitatively fed into the sulfur-burning furnace where it burns to form SO2 gas. SO2 gas flows into the SO2 absorbing column, within it SO2 gas is absorbed with water to form sulfureous acid with specified concentration. Sulfureous acid will store in the acid storage tank, from which it is fed by pump into the steeping tanks as steeping liquid. The tail gas coming from the SO2 absorbing column will be vented to air by the tail gas fan.

Maize steeping

The maize in the silos is quantitatively fed by the electronic weigher from the silo into the hydro-feeding trough, by which the maize comes into the feed tank where some heavy impurities will settle down by gravity difference and separated out from maize.

Germ separation

After completion of steeping the wet maize is discharged from the steeping tank and pumped into the maize dewatering screen where the steeping liquid is separated from it. Then the wet maize goes into the wet maize bin.

The top-stream from the hydro-cyclone, which contains mainly germs, will pass through the gravity crank screens in series, in which they are washed with recycle water. Then the liquid is removed from the germs by the screen and the dewatering machine. After that the wet germs are fed into the dryer where they are dried by heating with steam, and the dry germs are available, which shall be packed and kept in the by-product warehouse for sale to the oil mill as feed for production of corn oil.

The crude starch milk streams coming from the fiber crank screen group and the fiber screen will be collected in the crude starch milk pond. Before being fed into the gluten separating machines the starch milk will pass through the sand remover and the rotary filter to remove sand and other foreign substances. Then the starch milk is fed into two gluten-separating machines where the gluten is separated from the starch.

After fully separating gluten from the starch milk, the starch milk is pumped into the hydro-cyclone group, which consists of 12 sets of the hydro-cyclones and 11 sets of recycle pumps, where the starch is washed with drinking water for fully removing gluten from starch. The clean starch milk is pumped to the overhead tank, and will be used as feed for the drying system.

Starch drying

The starch drying system includes the starch-dewatering machine, the hot air-flow dryer, cyclone collector, fans, air heater as well as some conveyors and feeders. First the clean starch milk flows into the starch-dewatering machine where the liquid is removed from it, then the wet starch is fed by screw feeder into the drying system where it contacts with hot air generated by the steam-heater, in result water contained in the wet starch is evaporated out and the dry starch powder is available.

We have more than 200 running oil processing plant around the world and have extensive experience in oil mill construction. If you are interested in our Corn Starch Processing Line, please leave us a message.