Wheat milling

Wheat milling process is mainly used the strength difference between endosperm and cortex, using grinding, sifting, clear powder equipment to make net wheat cortex, embryo and endosperm separated and the endosperm into flour with a certain degree of fineness, while isolated by-products.

The wheat milling equipment manufactured by Huatai absorbs foreign advanced technology parameters, with advantages of high yield, good quality flour, low ash, low consumption. Among wheat with three screens two dozen two to stone wash wheat cleaning process, using pomace pink heart between both, the outer skin mill sieve classification, the heart of the latest technology assisted grinding crash powder, low power consumption, reasonable structure, the advanced technology praised by customer!

Wheat Flour Process flow

Wheat raw grains→threshing wheat→clean→wheat wetting→shelling→grind→screening→square plansifter→flour cleaning→package→finished products→finished product inspection

Wheat Milling Process Steps

Cleaning and moisture conditioning: First, the wheat needs to be cleaned and tempered to remove impurities and unnecessary parts, such as wheat awns and part of the bran, and then adjusted to the appropriate humidity to facilitate subsequent processing.

Separation: During the milling process, the endosperm (the main component of flour), wheat bran (peel and seed coat) and wheat germ in the wheat kernel are separated. This step is critical in flour making, as the quality of the flour depends largely on how well these parts separate.

Grinding: Grind the separated endosperm into powder. This process usually involves physical methods such as grinding and sifting to ensure that the endosperm is finely ground into flour.

By-products: During the milling process, some by-products are produced, such as bran, bran meal feed and wheat germ. Although these by-products are not the main part of flour, they still have certain nutritional value and uses.

Classification of flour: According to the protein content, flour can be divided into high-gluten flour, medium-gluten flour, low-gluten flour and gluten-free flour. This classification is mainly based on the uses of flour, such as baking, cooking, etc.

Milling process: The length and details of the milling process depend on the required precision of the flour. For example, when producing high-precision flour, more grinding passes and more detailed processing are used to ensure that the amount of bran mixed in the flour is low. On the contrary, when producing low-precision flour, the number of grinding passes and fineness will be reduced accordingly.

Home production: When making whole wheat flour at home, it involves steps such as washing, drying the wheat, and using a food processor to grind it. Although the flour produced this way is more primitive, it retains the natural flavor and nutrients of wheat.

Wheat milling is not only a process of converting wheat grains into flour, but also a process involving multiple steps and technical details designed to maximize the nutritional value of wheat and meet different use needs.

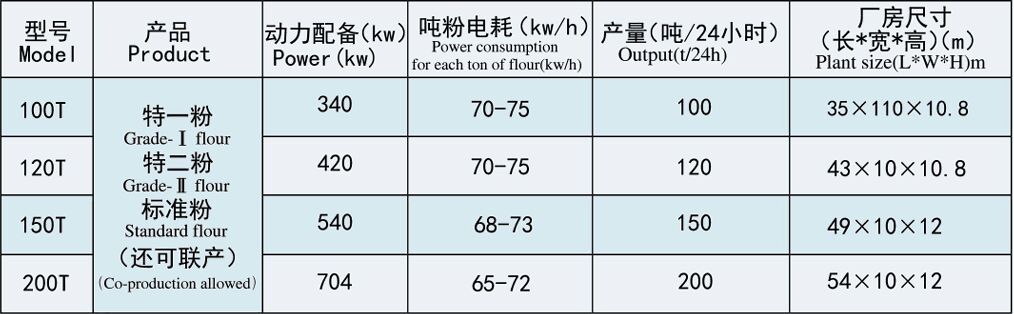

Wheat flour mill processing equipment division stand-alone devices and equipment, can co-production special flour, flour, marking powder, 200 tons more than the specifications of flour can produce all kinds of food to meet the needs of the food industry. The device is a small investment, high degree of automation, stable performance, quick, low energy consumption, high efficiency, there are a number of varieties for customers to choose.

Wheat flour mill plant model

Huatai Machinery is committed to providing customers with high-quality wheat flour mill machine and maize flour mill machinery, enabling them to profit from their flour milling businesses. We specialize in undertaking turnkey projects for wheat flour mill plants.